Fish feed factories is a good market segment for Hybrid High temperature heat pumps because of large driers.

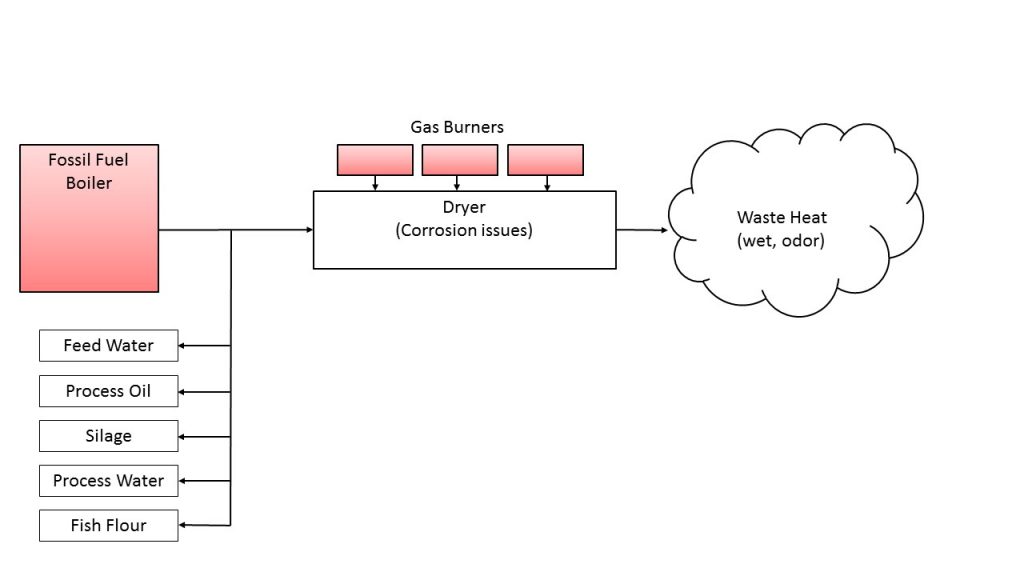

Most larger fish feed factories have gas burners or steam for heating the different zones in the belt dryer. They also have a large demand for heat for process water, preheating of water to the steam boiler, tap water, heating of different animalic oils and preheating of air to the driers.

The driers have moist and hot exhaust air from the driers.

Traditional fish feed factories usually produce heat in boilers producing steam or hot water which is distributed in the factory.

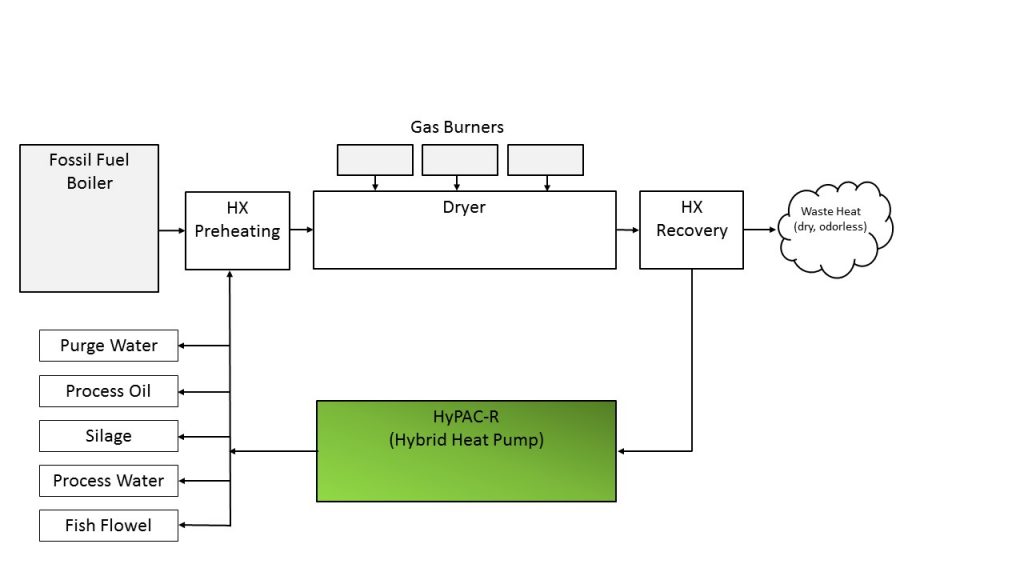

The most energy efficient and modern factories recover the waste heat from the driers to feed thermal waste energy into heat pumps for heating demands in the factory.

By cooling this exhaust air not only can you recover energy, but often also reduce smell in the surrounding of the factory.

For optimized operating time and energy recovery, thermal accumulation tanks are used at the different temperature levels in the factory.

The heat source and heat demands are usually present at the same time of day which makes it better to run a heat pump in the factory

TRADITIONAL FISH FEED FACTORY:

FISH FEED FACTORY WITH HYBRID HEAT PUMP INSTALLATION: